Product Name | Ethylene Glycol Distearate |

| CAS | 627-83-8 |

Quality Standard | Standard |

Product Grade | Cationic Emulsifiers |

Place of Origin | China |

Dangerous Goods | No

|

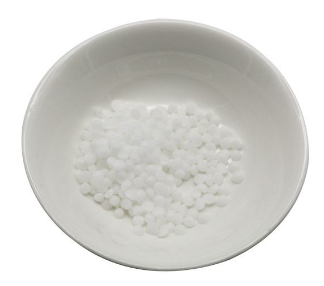

Ethylene Glycol Distearate (abbreviated as EGDS) is a type of non-ionic surfactant and ester wax, synthesized through the esterification reaction of ethylene glycol and stearic acid. Its molecular structure consists of two stearic acid chains linked by an ethylene glycol backbone, giving it dual characteristics of surfactancy and waxiness. Under room temperature conditions, EGDS exists as a white, odorless flaky or powdery solid with a melting point ranging from 60°C to 65°C. It is insoluble in cold water but can disperse in hot water to form a stable, pearlescent dispersion; it is also soluble in organic solvents such as ethanol, ether, and chloroform.

As a non-ionic compound, EGDS has good compatibility with most anionic, cationic, and non-ionic surfactants. It exhibits excellent stability across a wide pH range (4.0–10.0) and is not prone to hydrolysis or decomposition under normal formulation and processing conditions. These properties make it a versatile functional ingredient widely used in the daily chemical, textile, and plastic processing industries.

Pearlescent EffectEGDS is most renowned for its ability to impart a smooth, elegant pearlescent luster to aqueous surfactant systems. When dispersed in hot water and cooled, it crystallizes into fine, lamellar particles that scatter light, creating a distinctive pearlescent appearance in products such as shampoos, body washes, and liquid soaps.

Thickening and Stabilizing CapacityIt can enhance the viscosity of surfactant solutions by increasing the structural viscosity of the system, helping to maintain a stable product consistency. Additionally, EGDS improves the stability of emulsions, preventing phase separation of oil and water components during storage and extending the shelf life of formulations.

Softening and Emollient PropertiesWith its wax-like structure, EGDS acts as a mild emollient. When applied to the skin or hair, it forms a thin, breathable protective film that locks in moisture, reduces water loss, and imparts a soft, smooth feel without causing greasiness.

Low Irritation and BiocompatibilityEGDS is non-toxic and has low irritation to the skin and eyes, meeting the safety standards of cosmetic and personal care products. It is suitable for use in formulations targeting sensitive skin and baby care products.

This is the primary application field of EGDS, where it is valued for its pearlescent, thickening, and emollient effects.

- Hair Care Products: Added to shampoos, conditioners, and hair rinses, it not only creates an attractive pearlescent look but also thickens the product, improves combability, and leaves hair soft and glossy. The recommended dosage ranges from 1.0% to 3.0%.

- Body Cleansing Products: Used in body washes, hand soaps, and shower gels to enhance product aesthetics and texture, while providing a mild emollient effect that prevents skin dryness after cleansing.

- Skin Care Products: Incorporated into moisturizing lotions, creams, and facial cleansers as a co-emulsifier and stabilizer, helping to maintain emulsion stability and improve skin feel.

- Textile Softeners: EGDS is used as a component of fabric softening formulations, especially for cotton, wool, and synthetic fibers. It reduces fiber friction, imparts a smooth hand feel, and enhances the drapability of fabrics without affecting their breathability.

- Leather Finishing Agents: Applied in leather finishing processes to improve the surface smoothness and gloss of leather products, while enhancing the wear resistance and water repellency of the leather surface.

- Plastic Processing: Used as a lubricant and mold release agent in the production of polyethylene, polypropylene, and other plastics. It reduces the friction between plastic melts and mold surfaces, enabling smooth demolding and improving the surface finish of plastic products.

- Pesticide Formulations: Serves as an emulsifier and stabilizer in pesticide emulsifiable concentrates, helping to disperse oil-soluble active ingredients in water and improve the stability and efficacy of pesticide formulations.

- Storage Conditions: Store EGDS in a cool, dry, and well-ventilated warehouse, away from direct sunlight and high temperatures (storage temperature should not exceed 40°C). Keep the packaging sealed to prevent moisture absorption and caking, which may affect its dispersibility.

- Usage Tips: To achieve the best pearlescent effect, heat EGDS to 70°C–80°C along with the surfactant system, stir thoroughly to dissolve or disperse it evenly, and then cool the mixture slowly to room temperature to promote crystal formation.

- Safety Precautions: EGDS is non-hazardous and safe for routine handling. During industrial processing, avoid inhaling large amounts of dust; if accidental contact with eyes occurs, rinse thoroughly with clean water.

Product Introduction

Product Introduction