Wear-Resistant Steel Balls: The "Hardcore Tool" for Industrial Grinding

Wear-resistant steel balls are industrial consumables with high hardness and wear resistance as their core characteristics. They are mainly made of carbon steel, alloy steel and other materials through forging, rolling or casting processes, and are widely used in various grinding scenarios. Their core advantage lies in achieving a balance between hardness and toughness through material optimization and process upgrading, which can reduce wear, extend service life and lower industrial production costs in high-intensity grinding operations.

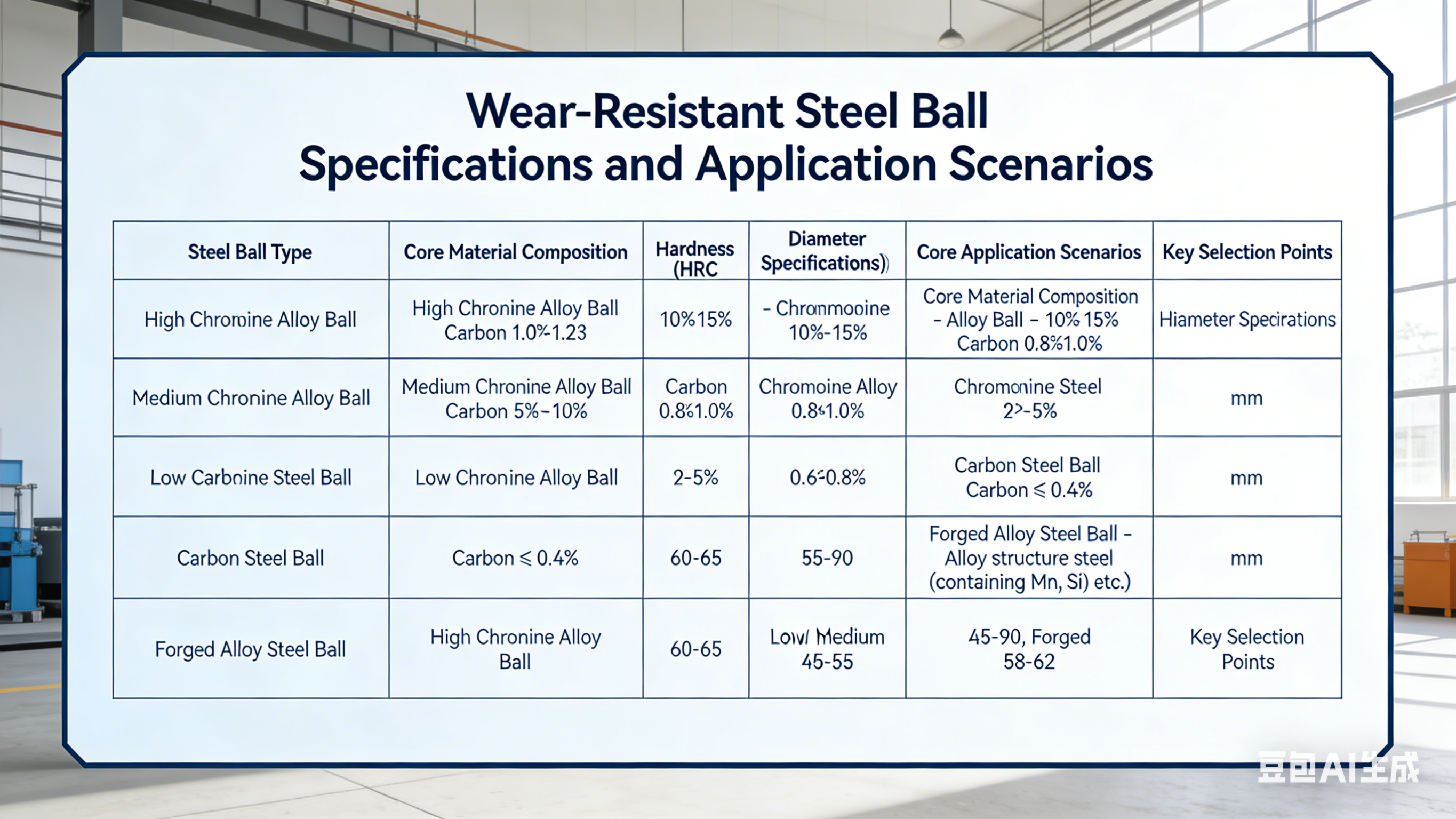

From the perspective of material classification, wear-resistant steel balls mainly include high-chromium alloy balls, low-chromium alloy balls, carbon steel balls, etc. High-chromium alloy balls, strengthened by chromium, have a hardness of over HRC60 and the best wear resistance, making them suitable for grinding high-hardness materials. Low-chromium alloy balls offer outstanding cost performance, balancing wear resistance and economy, and are a universal grinding choice. Carbon steel balls, with the advantage of low cost, are suitable for scenarios with low requirements for grinding precision.

In terms of application fields, wear-resistant steel balls are widely used in multiple industrial sectors. In mining, they are core components of ball mills, used for crushing and grinding mineral raw materials such as iron ore and copper ore to ensure mineral processing efficiency. In the building materials industry, wear-resistant steel balls are needed to grind clinker and gypsum during cement production to improve cement grade. In the chemical industry, they are used for grinding various chemical raw materials to facilitate the production of fine chemical products. In addition, wear-resistant steel balls also play an irreplaceable grinding role in industries such as electric power, metallurgy and ceramics.

With the upgrading of industrial intelligence, wear-resistant steel balls are developing towards high precision, low loss and customization. By adopting advanced heat treatment processes and material formulas, the new generation of wear-resistant steel balls not only has further improved wear resistance, but also can adapt to the grinding needs of different working conditions, providing strong support for the efficiency and energy saving of industrial production.

Recommended Related Images (HD versions available via direct search)

Finished Wear-Resistant Steel Balls: Show the stacking effect of wear-resistant steel balls of different specifications and materials, highlighting their metallic luster and regular shape;

Ball Mill Working Scene: Present the dynamic scene of wear-resistant steel balls mixing and grinding with materials inside the ball mill to reflect practical application;

Material Comparison Chart: Display the material differences between high-chromium alloy balls and ordinary carbon steel balls through microscopic structure photos, intuitively presenting the principle of wear resistance;

Industrial Application Scene: Shoot the use site of wear-resistant steel balls in mineral processing plants, cement production workshops and other places to connect with specific application fields.

Core Selection Guide

Diameter Specification: The larger the ball mill volume and the higher the material hardness, the larger diameter (30-50mm) is recommended; fine grinding and small equipment are suitable for small diameter (12-25mm);

Working Condition Adaptation: High-speed ball mills prioritize high-chromium/forged steel balls (impact resistance), while low-speed equipment can choose medium and low-chromium balls (cost control);

Special Scenarios: For grinding corrosive materials, additional corrosion-resistant high-chromium balls (added with nickel and molybdenum elements) are required. For high-temperature working conditions (such as cement kiln tails), medium and high-chromium balls with strong heat resistance are preferred.